Grooved Fitting System

Grooved Piping System in Stainless Steel

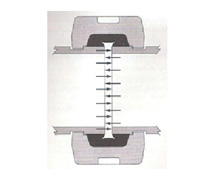

A grooved pipe joint is comprised of four elements: the grooved pipe, the gasket, the coupling housing, and the nuts and bolts. The groove is made by cold forming or machining a groove into the pipe ends. A gasket encompassed by the coupling housing forms a seal on the two pipe ends, and the key sections of the coupling housing engage the grooves. The bolts and nuts are tightened with a socket wrench or impact wrench. In the installed state, the coupling housing encases the gasket and engages the grooves around the circumference of the pipe to create a leak-tight seal in a self-restrained pipe joint. There are two basic coupling styles that can be used on grooved pipe: flexible and rigid.

Flange Adapter Grooved

Reducing Tee Grooved

90° Elbow with Short Radius

Reducing Tee F/Threaded

45° Elbow

11.25° Elbow

Cross Grooved

22.5° Elbow

Tee with Long Radius

Rigid Coupling

Reducing Cross Grooved

Tee With Shoet Radius

Flexible Coupling

Reducer Grooved

Rigid/Flexible Coupling - 2.5 mpa

Reducing Flexible Coupling

Reducer F/Threaded

Mech Tee Grooved

Mech Tee F/Threaded

U-Bolted Mech Tee F/Threaded

Flange Grooved

Enconcentric Reducer Grooved

Cap

- Faster Pipe Joints

- Ease and Speed of Maintenance

- Union at every Joint Offers Flexibility

- Reliability

- Economical to install

- Reduced Noise and Vibrations

- Corrosion Resistant thin Walled pipes (cheaper to use)

Benefits of Grooved Piping System

Coupling Housing Segment

A flexible coupling accommodates pipe deflection and or non-alignment as below : if nominal diameter

Gasket

With the removal of just a few bolts, you can easily access the system for cleaning maintenance, change or system expansion

Coupling Housing Segment

The C-shaped rubber gasket provide excellent self-sealing capabilities in both low and high pressure service as well as under certain vacuum conditions.

Coupling are non-directive and pipe can be rotated 360 during installation

Coupling Housing Segment

Coupling keys engage the full circumference of the grooves and provide significant pressure and end load restraint pipe movement from internal and exernal forces.

Bold/Nut

The design and construction of the coupling with elastomeric gaskets can provide significant noise and vibration absorption as well as seismic stress.

PressG is now introducing UL Listed and FM approved Grooved fittings from reputed manufacturers

Ductile Iron Grooved Fittings

| Feature | Ductile Iron Fittings | Forged Fittings | Remarks |

| Internationally Used in Fire Fighting | Yes | No | Internationally chosen Europe as well as USA |

| Internationally Approval | Yes, UL & Fm | No Approval | Fm Approval is basic criterion for fire fighting fittings |

| Test Pressure Working Pressure | 1500 psi / 500 psi | 1000 psi | Why use high pressure Fitting when actual pressure is 300 psi or less |

| Cost / Price | Low, 30-40% cheaper than Forget Fittings | Very High |

Our Products

Why SS is Better?

Stainless Steel grades 304/316L have better corrosion resistance. Even copper has Green corrosion of Copper.

>> See Full Comparision Chart